|

|

|

|

Image is illustrative

|

Power Transition Cable, Bayonet, MP-series, 0.5m, Allen-Bradley Code:

2090-CPWM4E2-14TR

Price (indicative)

Manufacturer

:

|

Availability:

ask for dd

|

Weight:

0.32 kg/pc

|

Volume:

0.0012 m3/pc

|

|

|

|

|

Power Transition Cable, Bayonet, MP-series, 0.5m, Allen-Bradley

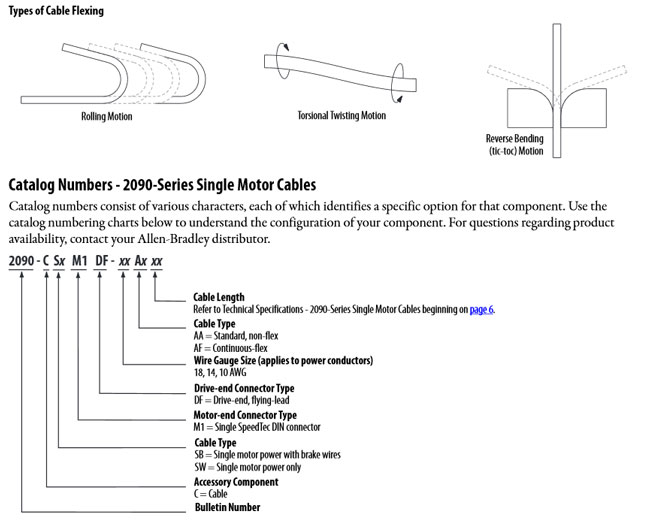

2090-Series Single Motor Cables

Allen-Bradley single motor cables combine motor power, feedback, and brake conductors all in a single shielded cable. Standard (non-flex) motor cables with rugged SpeedTec DIN connectors are designed for use with Kinetix 5500 drive systems and intended for static applications. Continuous-flex rated cables, intended for rolling, twisting, and reverse bending applications, are also available.

IMPORTANT

Due to the unique characteristics of single-cable technology, designed for and tested with Kinetix 5500 drives and Kinetix VPmotors, building your own cables or using third-party cable is not an option.

Flying-lead motor power, feedback, and (optional) brake conductors terminate at the drive by using the 2198-KITCON-DSL feedback connector kit. The kit is included with Kinetix 5500 servo drives. Refer to the Kinetix Servo Drives Specifications Technical Data, publication GMC-TD003, for more information on the Kinetix 5500 drive and connector kit.

Continuous-flex single motor cables have a minimum bend radius of 10 times the cable diameter.

These 2090-Series motor cables with SpeedTec DIN connectors, designed by Rockwell Automation for optimal performance with Kinetix 5500 servo drives and Kinetix VP servo motors, offer best-in-class features and standards compliance. The single-cable design includes power, feedback, and brake conductors. The continuous-flex cable option, cable lengths in 1 m (3.3 in.) increments, and SpeedTec connectors provide machine builders with complete control of the cable requirements in their machines.

Single Motor Cable Features

UL Listed PLTC - ER construction.

CSA AWM I/II A/B 1000V, 105 °C (221 °F) construction.

Low capacitance design to maximize system power density.

Hybrid cable construction permits power and signal conductors in a single cable

– 1/4-turn SpeedTec connection system.

Encoder communication data pair with state of the art noise rejection.

DESINA compliant jacket (orange) coloring for easy identification and separation of cables in a machine.

Continuous flex cables are suitable for 20 million flex-cycles in rolling applications, 10 million cycles in torsional applications, and 10 million cycles in bending (tic-toc) applications (see Types of Cable Flexing on page 3 from Downloadable files).

Cable features overall tinned copper braid with aluminium/polyester tape, delivering 100% coverage for excellent EMC/EMI performance.

Cables are included in the Rockwell Automation® servo system Declaration of Conformity (DoC).

|

|

|

|

|

File description

|

File type

|

Download link

|

|

|

|

|

|

Catalogue

|

PDF

|

Download link

|

|

|

|

|

|